Reinforced angle brackets

Reinforced angle brackets are suitable for structural applications in framing and wood-frame houses.

Product Details

Features

Material

- Galvanized steel S250GD + Z275 according to NF EN 10346.

Benefits

- High rigidity through double-sided splash back

- High load values

Application

Suitable On

- Supporting member: solid wood, glued-laminated wood, concrete, steel, etc.

- Supported member: solid wood, composite lumber, glued-laminated wood, triangular trusses, profiles, etc.

When to Use

- Fastening of small trusses.

- Cladding plates, cladding uprights.

- Rafter anchors, cantilevers, headers, etc.

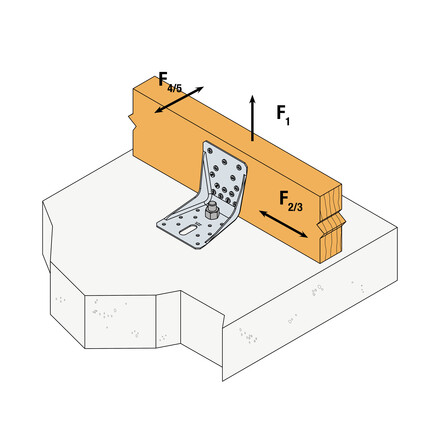

Technical Data

Wood/wood connection beam/beam type - assembly with 2 angle brackets

| References | Product capacities - Timber to timber - Full nailing | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Fasteners | Characteristic capacities - Timber C24 - 2 angle brackets per connection [kN] | ||||||||||||||||

| Joist | Flange B | R1.k | R2.k = R3.k | R4.k = R5.k(1) | |||||||||||||

| Qty | Qty | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CSA5.0x40 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CSA5.0x40 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CSA5.0x40 | |

| ABR9015 | 8 | 10 | 3.45 | 4.1 | 5.4 | 6.6 | 13.2 | 6.3 | 7.1 | 8 | 9.6 | 10.5 | - | - | - | - | 5 /kmod^0,4 |

| ABR100 | 10 | 14 | 9.7 | 11.7 | 15.7 | 19.7 | min (26,7/kmod^0,2 ; 27 /kmod) | 9.6 | 12.8 | 14.2 | 16.7 | 20.3 | 2.4 | 4.2 | 5.1 | 5.1 | 5.1 |

1) b = 75 mm ; e = 130 mm

To obtain the resistance values for a single bracket, the values in the above table should be divided by two, provided that the supported beam is locked in rotation. Please consult our ETA-06/0106 if the beam is free to rotate.

Wood/wood connection post/beam type - assembly with 2 angle brackets

| References | Product capacities - Timber beam to Concrete | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Fasteners | Characteristic capacities - Timber C24 - 2 angle brackets per connection [kN] | |||||||||||

| Joist | Flange B | R1.k | R2.k = R3.k | R4.k = R5.k | ||||||||

| Qty | Type | Qty | Type | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x35 | CNA4.0x40 | |

| ABR100 | 1 | Ø10 | 10 | CNA* | min (17,1; 21,6 /kmod) | min (20,6; 21,6 /kmod) | min (26,6; 21,6 /kmod) | 7.2 | 8.7 | 10.9 | 8.6 | 10.4 |

* Refer to Characteristic Capacity table columns for type of fasteners that can be used in Flange A. Capacities vary depending on fastener type used.

To obtain the resistance values for a single bracket, the values in the above table should be divided by two, provided that the supported beam is locked in rotation. Please consult our ETA-06/0106 if the beam is free to rotate.

Characteristic capacities - Timber to steel - Connection with 2 brackets

| References | Product capacities - Timber to Steel | ||||

|---|---|---|---|---|---|

| Number of Fasteners | Characteristic capacities - Timber C24 - 2 angle brackets per connection [kN] | ||||

| Joist | Flange B | R1.k | |||

| Qty | Type | Qty | Type | CNA4.0x60 | |

| ABR100 | 10 | CNA* | 4 | PDPA-75 | 21.5 |

To obtain the resistance values for a single bracket, the values in the above table should be divided by two, provided that the supported beam is locked in rotation. Please consult our ETA-06/0106 if the beam is free to rotate.

Simplified characteristic capacities - Timber to concrete - Connection with 2 brackets

| References | Simplified product capacities - Timber to Concrete | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Number of Fasteners | Simplified characteristic capacities - Timber C24 - 2 angle brackets per connection [kN] | |||||||||

| Joist | Flange B | R1.k** | R2.k = R3.k | |||||||

| Qty | Type | Qty | Type | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | |

| ABR100 | 1 | Ø10 | 10 | CNA* | 17.1 | 20.6 | 24 | 7.2 | 8.7 | 10.9 |

* Refer to Characteristic Capacity table columns for type of fasteners that can be used in Flange A. Capacities vary depending on fastener type used.

Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions deepend on the concrete type, spacing and edge distances.

** The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) – kmod = 0.9. For other load duration and service class, please refer to the ETA to get more accurate capacities

With combined loads, the following formula shall be fulfilled

To obtain the resistance values for a single bracket, the values in the above table should be divided by two, provided that the supported beam is locked in rotation. Please consult our ETA-06/0106 if the beam is free to rotate.

Characteristic capacities - Timber beam to timber beam - Ø10 connector screws - 2 angle brackets

| References | Product capacities - Timber beam to timber beam - Ø10 connector screws - 2 angle brackets | |||||

|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 2 angle brackets per connection [kN] | |||||

| Flange A | Flange B | R1.k | R2.k = R3.k | |||

| Qty | Type | Qty | Type | SSH10x40 | SSH10x40 | |

| ABR100 | 2 | SSH | 1 | SSH | 5.2 | 2.7 |

Characteristic capacities - Timber beam to concrete - Ø10 connector screws - 2 angle brackets

| References | Product capacities - Timber beam to rigid support - Ø10 connector screws - 2 angle brackets | |||||

|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 2 angle brackets per connection [kN] | |||||

| Flange A | Flange B | R1.k | R2.k = R3.k | |||

| Qty | Type | Qty | Type | SSH10x40 | SSH10x40 | |

| ABR100 | 1 | Ø10 | 1 | SSH | 5.7 | 4.1 |

Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions are FM753, AT-HP, depending on the concrete type, spacing and edge distances.

Installation

Installation

Fixing

On wood:

- CNA annular ring-shank nails dia. 4.0 x 35 or dia. 4.0 x 50 mm.

- CSA screws dia. 5.0 x 35 mm or CSA screws dia. 5.0 x 40 mm.

- Bolts.

- LAG screws.

On concrete:

Concrete substrate

- Mechanical anchor: WA M10-78/5 OR WA M12-104/5 pin.

- Chemical anchor: AT-HP resin + LMAS M10-120/25 or LMAS M12-150/35 threaded rod.

Hollow masonry substrate:

- Chemical anchor: AT-HP or POLY-GP resin + LMAS M12-150/35 threaded rod + SH M16-130 screen.

On steel:

- Bolts.