Reinforced Angle Bracket for CLT

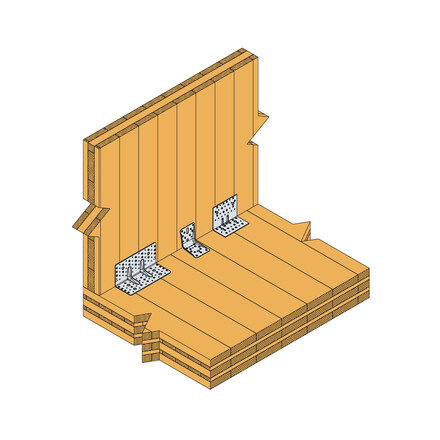

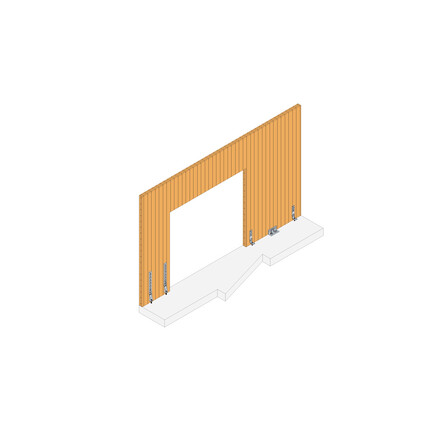

Reinforced angle bracket ABR255 has been especially developed to fix CLT panels on wood or concrete support. Very versatile, it is particularly resistant to shear loads thanks to its optimized geometry.

Product Details

Features

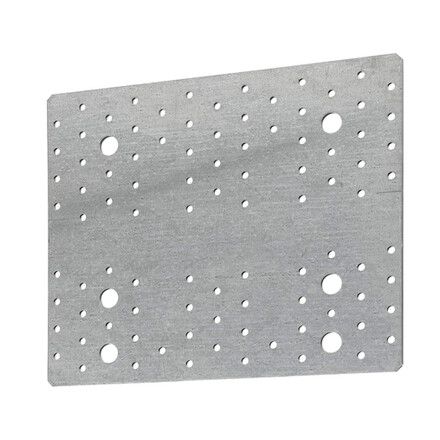

Material

- Galvanized steel S250GD + Z275 according to EN 10346

- Thickness 3 mm

Benefits

- Ideal for use in CLT buildings

- Great versatility: can be installed on wooden support and concrete support

- High performance for horizontal (F2 / F3) and vertical (F1) loads directions

Application

Suitable On

- Supporting member: solid wood, glulam, CLT, concrete, steel

- Supported member: solid wood, glulam, CLT

Scope

- Solid panels

- Cross laminated panel (CLT)

Technical Data

Product characteristic capacities - Timber to timber - 1 angle bracket - Full nailing - Nailing pattern 1

| References | Product capacities - Timber to timber - Full nailing - Nailing pattern 1 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||

| Qty | Qty | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | |||

| ABR255 | 52 | 41 | 14,1 / kmod^0,4 | 16 / kmod^0,4 | 19,5/ kmod^0,4 | 22,5 / kmod^0,4 | 33.5 | 37 | 45.9 | 50.5 | 12.5 | 14.9 | 18.2 | 21.1 | min (14.3 / kmod^0,4; 13.4/kmod) | min (15.7 / kmod^0,4; 13.4/kmod) | min (18.8 / kmod^0,4; 13.4/kmod) | 13.4/kmod |

The value in the table above can be used if the panel can't rotate.

Characteristic Capacities - Timber to Timber - 1 Angle Bracket - Full Nailing - Nailing Pattern 1

| References | Product capacities - Timber to timber – Full nailing - Nailing Pattern 1 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle brackets per connection [kN] | |||||||||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||

| Qty | Qty | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | |||

| ABR255 | 52 | 41 | 14.7 | 16.7 | 20.3 | 23.5 | 33.5 | 37 | 45.9 | 50.5 | 12.5 | 14.9 | 18.2 | 21.1 | 14.8 | 14.8 | 14.8 | 14.8 |

- The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) where kmod = 0.9.

- For other load duration and service class, please refer to the ETA.

Product characteristic capacities - Timber to timber - 1 angle bracket - Partial nailing - Nailing pattern 2

| References | Product capacities - Timber to timber - Partial nailing - Nailing pattern 2 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||

| Qty | Qty | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | |||

| ABR255 | 30 | 23 | 12,2 / kmod^0,4 | 13,7 / kmod^0,4 | 16,5 / kmod^0,4 | 19,5 / kmod^0,4 | 27.4 | 30.5 | 38 | 42.1 | 12.2 | 13.8 | 16.9 | 19.5 | min (11.5 ; 13.9/kmod) | min (13.6 ; 13.9/kmod) | min (18 ; 13.9/kmod) | min (22 ; 13.9/kmod) |

The value in the table above can be used if the panel can't rotate.

Characteristic Capacities - Timber to Timber - 1 Angle Bracket - Partial Nailing - Nailing Pattern 2

| References | Product capacities - Timber to timber – Partial nailing - Nailing pattern 2 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||

| Qty | Qty | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | |||

| ABR255 | 30 | 23 | 12.7 | 14.3 | 17.2 | 20.3 | 27.4 | 30.5 | 38 | 42.1 | 12.2 | 13.8 | 16.9 | 19.5 | 11.5 | 13.6 | 15.4 | 15.4 |

- The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) where kmod = 0.9.

- For other load duration and service class, please refer to the ETA.

Product characteristic capacities - Timber to timber - 1 angle bracket - Partial nailing - Nailing pattern 4

| References | Product capacities - Timber to timber - Partial nailing - Nailing pattern 4 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||

| Flange A | Flange B | R1,k | R2,k = R3,k | R4.k | R5.k | |||||

| Qty | Qty | CNA4,0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||

| CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |||

| ABR255 | 24 | 21 | 15,6/kmod^0,4 | 18,1/kmod^0,4 | 28.6 | 31.4 | 15.9 | 18.3 | 10.8/kmod^0.3 | min (12.7/kmod^0,3 ; 12.8 / kmod) |

The value in the table above can be used if the panel can't rotate.

Nailing pattern 4 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.

Characteristic Capacities - Timber to Timber - 1 Angle Bracket - Partial Nailing - Nailing Pattern 4

| References | Product capacities - Timber to timber - Partial nailing - Nailing pattern 4 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||

| Qty | Qty | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255 | 24 | 21 | 16.2 | 18.8 | 28.6 | 31.4 | 15.9 | 18.3 | 11.1 | 16.7 |

- The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) where kmod = 0.9.

- For other load duration and service class, please refer to the ETA.

Product characteristic capacities - Timber to timber - 1 angle bracket - Partial nailing - Nailing pattern 5

| References | Product capacities - Timber to timber - Partial nailing - Nailing pattern 5 | |||

|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||

| Flange A | Flange B | R1,k | R2,k = R3,k | |

| Qty | Qty | CSA5.0x50 | CSA5.0x50 | |

| ABR255 | 46 | 41 | 23,6 / kmod | 51.7 |

The value in the table above can be used if the panel can't rotate.

Nailing pattern 5 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.

Product characteristic capacities - Timber to timber - 1 angle bracket - Partial nailing - Nailing pattern 6

| References | Product capacities - Timber to timber - Partial nailing - Nailing pattern 6 | |||||

|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||

| Flange A | Flange B | R1.k | R2,k = R3,k | |||

| Qty | Qty | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255 | 32 | 21 | - | - | 36.1 | 39.2 |

The value in the table above can be used if the panel can't rotate.

Nailing pattern 6 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.

Characteristic Capacities - CLT Beam to CLT Beam - Ø12 Connector Screws - 1 Angle Bracket

| References | Product capacities - CLT beam to CLT beam - Ø12 connector screws - 2 angle brackets | |||||

|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 2 angle brackets per connection [kN] | |||||

| Flange A | Flange B | R1.k | R2.k = R3.k | |||

| Qty | Type | Qty | Type | SSH12x80 | SSH12x80 | |

| ABR255 | 2 | SSH | 4 | SSH | 13.4 | 16.6 |

Product characteristic capacities - Timber to rigid support - 1 angle bracket - Full nailing - Nailing pattern 1

| References | Product capacities - Timber to Concrete - Full nailing - Nailing pattern 1 | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||||||

| Qty | Type | Qty | Type | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||||

| 35-50-60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | 35-50-60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | |||||

| ABR255 | 52 | CNA | 2 | Ø12 | 22 / kmod | 22 / kmod | 22 / kmod | 22 / kmod | 22 / kmod | 33 | 36 | min (45,3 ; 42,9/kmod) | min (49,2 ; 42,9/kmod) | 18.3 / kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | min (17.1/kmod^0.25 ; 17.7/kmod) | min (19.5/kmod^0.25 ; 17.7/kmod) | min (23.5/kmod^0.25 ; 17.7/kmod) | min (27.3/kmod^0.25 ; 17.7/kmod) |

| ABR255SO | 56 | CNA | 2 | Ø12 | 22,9 / kmod | 22,9/kmod | 22,9/kmod | 22,9/kmod | 22,9/kmod | 29.2 | 32.5 | 38.6 | - | 18,6 / kmod^0,66 | 18,6/kmod^0,66 | 18,6/kmod^0,66 | 18,6/kmod^0,66 | 18,6/kmod^0,66 | 5,05/kmod | 5,05/kmod | 5,05/kmod | 5,05/kmod |

The value in the table above can be used if the panel can't rotate.

The anchors must be checked seperatly using tension value of 1.1*F1, 1*F2 and 1.1*F5

Characteristic Capacities - Timber to Rigid Support - 1 Angle Bracket - Full Nailing - Nailing Pattern 1

| References | Product capacities - Timber to Concrete - Full nailing - Nailing Pattern 1 | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||||

| Qty | Type | Qty | Type | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | |||||

| ABR255 | 52 | CNA | 2 | Ø12 | 24.4 | 24.4 | 24.4 | 24.4 | 25.1 | 29.2 | 45.3 | 49.2 | 19.7 | 19.7 | 19.7 | 19.7 | 17.5 | 19.6 | 19.6 | 19.6 |

| ABR255SO | 56 | CNA | 2 | Ø12 | 20.8 | 20.8 | 20.8 | 20.8 | 29.2 | 32.5 | 38.6 | - | 17.1 | 17.1 | 17.1 | 17.1 | 4.6 | 4.6 | 4.6 | 4.6 |

- The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) where kmod = 0.9.

- For other load duration and service class, please refer to the ETA

- The bolt design resistance requirement R#,d is determined from (bolt factor x connection design load F#,d) for the required load direction and fastener. Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions are Set-XP, AT-HP, depending on the concrete type, spacing and edge distances.

Product characteristic capacities - Timber to rigid support - 1 angle bracket - Partial nailing - Nailing pattern 2

| References | Product capacities - Timber to Concrete - Partial nailing - Nailing pattern 2 | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | ||||||||||||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | ||||||||||||||||

| Qty | Type | Qty | Type | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | ||||||||||||||

| CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | 35-50-60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | |||||

| ABR255 | 30 | CNA | 2 | Ø12 | 15.94 | 18.8 | min (24,8 ; 22 / kmod) | min (30,3 ; 22 / kmod) | 21.6 | 23.7 | 29 | 32 | 18.3 / kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | 18.3/kmod^0,7 | 15.3/kmod^0.6 | 16.5/kmod^0.6 | min (19.9/kmod^0.4 ; 17.7 / kmod) | min (23.3/kmod^0.4 ; 17.7 / kmod) |

| ABR255SO | 19 | CNA | 2 | Ø12 | min (24,3; 22,9/kmod) | min (27,5; 22,9/kmod) | min (34,7; 22,9/kmod) | 22,9/kmod | 13.3 | 15.7 | 20.7 | - | 18,2 / kmod^0,66 | 18,2/kmod^0,66 | 18,2/kmod^0,66 | 18,2/kmod^0,66 | 18,2/kmod^0,66 | 5,05/kmod | 5,05/kmod | 5,05/kmod | 5,05/kmod |

The value in the table above can be used if the panel can't rotate.

The anchors must be checked seperatly using tension value of 1.1*F1, 1*F2 and 1.1*F5

Characteristic Capacities - Timber to Rigid Support - 1 Angle Bracket - Partial Nailing - Nailing Pattern 2

| References | Product capacities - Timber to Concrete - Partial nailing - Nailing Pattern 2 | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||||||||||

| Qty | Type | Qty | Type | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||||||||||

| CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | CNA4.0x35 | CNA4.0x40 | CNA4.0x50 | CNA4.0x60 | |||||

| ABR255 | 30 | CNA | 2 | Ø12 | 15.94 | 18.8 | 24.4 | 24.4 | 21.6 | 23.7 | 29.3 | 32 | 20.3 | 20.3 | 20.3 | 20.3 | 16.2 | 17.5 | 19.6 | 19.6 |

| ABR255SO | 19 | CNA | 2 | Ø12 | 20.8 | 20.8 | 20.8 | 2.08 | 13.3 | 15.7 | 20.7 | - | 17.1 | 17.1 | 17.1 | 17.1 | 4.6 | 4.6 | 4.6 | 4.6 |

- The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) where kmod = 0.9.

- For other load duration and service class, please refer to the ETA

- The bolt design resistance requirement R#,d is determined from (bolt factor x connection design load F#,d) for the required load direction and fastener. Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions are SET-XP and AT-HP, depending on the concrete type, spacing and edge distances.

Product characteristic capacities - Timber to rigid support - 1 angle bracket - Partial nailing - Nailing pattern 4

| References | Product capacities - Timber to Concrete - Partial Nailing - Nailing pattern 4 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||

| Flange A | Flange B | R1.k | R2.k = R2.k | R4.k | R5.k | |||||||

| Qty | Type | Qty | Type | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255SO | 26 | CNA | 2 | Ø12 | 22,9/kmod | 22,9/kmod | 21.7 | - | 18,2/kmod^0,66 | 18,2/kmod^0,66 | 5,05/kmod | 5,05/kmod |

The value in the table above can be used if the panel can't rotate.

The anchor capacities must be checked separatly by multiplying the F1 load by a factor 1.1, F2 load by a factor of 1 and F5 by a factor of 2.2.

Nailing pattern 4 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.

Characteristic Capacities - Timber to Rigid Support - 1 Angle Bracket - Partial Nailing - Nailing Pattern 4

| References | Product capacities - Timber to concrete - Partial nailing - Nailing pattern 4 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||

| Qty | Type | Qty | Type | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255SO | 26 | CNA | 2 | Ø12 | 20.8 | 20.8 | 21.7 | - | 17.1 | 17.1 | 4.6 | 4.6 |

- The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) where kmod = 0.9.

- For other load duration and service class, please refer to the ETA

- The bolt design resistance requirement R#,d is determined from (bolt factor x connection design load F#,d) for the required load direction and fastener. Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions are SET-XP and AT-HP, depending on the concrete type, spacing and edge distances.

Product characteristic capacities - Timber to rigid support - 1 angle bracket - Partial nailing - Nailing pattern 7

| References | Product capacities - Timber to concrete - Partial nailing - Nailing pattern 7 | |||||||

|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | |||||

| Qty | Type | Qty | Type | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255 | 30 | CNA | 2 | Ø12 | - | - | 39.8 | 42.5 |

| ABR255SO | - | - | - | - | - | - | - | - |

The value in the table above can be used if the panel can't rotate.

The anchor capacities must be checked separatly by multiplying the F2 load by a factor of 1.

Nailing pattern 7 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.

Product characteristic capacities - Timber to rigid support - 1 angle bracket - Partial nailing - Nailing pattern 8

| References | Product capacities - Timber to Concrete - Partial Nailing - Nailing pattern 8 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||

| Qty | Type | Qty | Type | CNA4.0x... | CNA4.0x... | CNA4.0x... | CNA4.0x... | |||||

| CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |||||

| ABR255 | 17 | CNA | 2 | Ø12 | 20 | 20 | 24.9 | 26.5 | 18.3/kmod^0.7 | 18.3/kmod^0.7 | 5.9/kmod^0.6 | 6.7/kmod^0.5 |

| ABR255SO | 30 | CNA | 2 | Ø12 | 22,9/kmod | 22,9/kmod | 26.1 | - | 18,2/kmod^0,66 | 18,2/kmod^0,66 | 5,05/kmod | 5,05/kmod |

The value in the table above can be used if the panel can't rotate.

The anchor capacities must be checked separatly by multiplying the F1 load by a factor 1.1, F2 load by a factor of 1 and F5 by a factor of 2.2.

Nailing pattern 8 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.

Characteristic Capacities - Timber to Rigid Support - 1 Angle Bracket - Partial Nailing - Nailing Pattern 8

| References | Product capacities - Timber to concrete - Partial nailing - Nailing pattern 8 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||||||||

| Flange A | Flange B | R1.k | R2.k = R3.k | R4.k | R5.k | |||||||

| Qty | Type | Qty | Type | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | CNA4.0x50 | CNA4.0x60 | |

| ABR255 | 17 | CNA | 2 | Ø12 | 23.4 | 25.8 | 24.9 | 26.5 | 19.7 | 19.7 | 6.2 | 7 |

| ABR255SO | 56 | CNA | 2 | Ø12 | 20.8 | 20.8 | 26.1 | - | 17.1 | 17.1 | 4.6 | 4.6 |

- The published characteristic capacity is based on short term load duration and service class 2 according to EC5 (EN 1995) where kmod = 0.9.

- For other load duration and service class, please refer to the ETA

- The bolt design resistance requirement R#,d is determined from (bolt factor x connection design load F#,d) for the required load direction and fastener. Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions are SET-XP and AT-HP, depending on the concrete type, spacing and edge distances.

Product characteristic capacities - Timber to rigid support - 1 angle bracket - Partial nailing - Nailing pattern 9

| References | Product capacities - Timber to Concrete - Partial nailing - Nailing pattern 9 | |||||

|---|---|---|---|---|---|---|

| Fasteners | Characteristic capacities - Timber C24 - 1 angle bracket per connection [kN] | |||||

| Flange A | Flange B | R1.k | R2.k = R3.k | |||

| Qty | Type | Qty | Type | CSA5.0x50 | CSA5.0x50 | |

| ABR255 | 35 | CSA | 2 | Ø12 | min (79,5 ; 22 / kmod) | min (58 ; 57,6 / kmod) |

| ABR255SO | - | - | - | - | - | - |

The value in the table above can be used if the panel can't rotate.

The anchor capacities must be checked separatly by multiplying the F1 load by a factor 1.1 and F2 load by a factor of 1.

Nailing pattern 9 has been specifically developed for CLT application. It can be used for applications with other timber based materials provided that the materials comply with the spacing and distances of fasteners in CLT.